Geodyn solutions zero waste

Once upon a time, the world was facing a massive problem: landfills were overflowing with garbage, pollution was soaring, and the environment was suffering. The situation was dire, and action needed to be taken before it was too late.

Geodyn solutions zero waste

Once upon a time, the world was facing a massive problem: landfills were overflowing with garbage, pollution was soaring, and the environment was suffering. The situation was dire, and action needed to be taken before it was too late. That’s when a team of innovative scientists and engineers came up with a revolutionary solution: the GeoDyn™ solutions Machine.

The GeoDyn™ Machine was unlike anything the world had seen before. It was a device that could accept virtually any form of organic refuse, from food waste to wood chips and more. It included multiple stages that efficiently reduced the size of the waste, compressed it and squeezed out its liquid, further pulverized the dehydrated content, and formed pellets that were dried and cooled.

One of the most impressive features of the GeoDyn™ solutions Machine was its ability to deal with ALL food waste, even hard-to-reduce materials like bones. And because the machine could be tailored in size, it could be installed at or near the site of food waste production. This meant that businesses, restaurants, and other food-producing environments could quickly and easily dispose of their waste without having to transport it to a landfill.

As word spread about the GeoDyn™ solutions Machines and its capabilities, businesses and governments around the world began to take notice. They saw the potential of this device to eliminate the global problem of waste management and help save the environment. And so, the machine’s production was scaled up, and waste processing capacities were increased to meet the growing demand.

Over time, the GeoDyn™ Machines became a staple in waste management operations across the globe. Landfills that were once overflowing with garbage became cleaner, and pollution levels began to decrease. The world was becoming a better place, all thanks to the innovative solution of a team of scientists and engineers who refused to accept the status quo.

Today, the GeoDyn™ solution Machine continues to be a critical part of waste management operations worldwide. It has eliminated a global problem and helped pave the way for a cleaner, more sustainable future. And who knows what other innovative solutions we may see in the future as we continue to work towards a better world.

From Trash to Energy: How Geodyn Solutions is Transforming Waste Management In a world increasingly burdened by Waste, finding innovative and sustainable …

In an era where sustainability and energy efficiency are not just goals but necessities, Geodyn Solutions stands at the forefront of environmental …

The medical industry faces a significant challenge in managing the vast amounts of waste it generates annually. With U.S. hospitals producing nearly …

In the quest for sustainable and efficient medical waste management solutions, Geodyn Solutions stands out with its innovative approach, integrating advanced technologies …

Geodyn Solutions’ Pyrolysis Technology: A Game-Changer in Medical Waste Disposal In the realm of medical waste management, finding solutions that are both …

Revolutionizing Medical Waste Management: Geodyn Solutions Leads with Valuable Resource Recovery In an era where sustainable healthcare practices are more critical than …

Leading the Charge in Sustainable Waste Management: Plasma Waste-to-Energy Solutions by Geodyn Solutions In an era where the quest for sustainable and …

In the dynamic landscape of waste management, plasma waste-to-energy technology emerges as a groundbreaking solution, offering a sustainable and innovative approach to …

In the realm of healthcare, the paramount importance of effective waste management cannot be overstated. The generation of medical waste, a byproduct …

Exploring the Cutting-Edge in Waste-to-Energy Technologies with Geodyn Solutions In an era where sustainability and efficient waste management are at the forefront …

As the world continues to face pressing environmental challenges, finding innovative solutions to manage organic waste and reduce greenhouse gas emissions has …

One of the most pressing global challenges in today’s society is the effective and efficient management of organic waste. The world generates …

In a small town in Kenya, nestled amid lush green hills, there lived a community that faced an ever-growing problem: waste tires. …

Trash-to-energy, also known as waste-to-energy, is the process of generating energy from waste materials. It involves converting non-recyclable waste into electricity, heat, …

In an era where sustainable solutions are increasingly necessary, the conversion of organic waste into energy presents an exciting opportunity. Transforming organic …

In the face of mounting environmental challenges, the concept of zero waste has gained significant attention. One key aspect of zero waste …

Geodyn Solutions is redefining the landscape of landfill remediation with an innovative, multi-faceted approach that combines cutting-edge waste-to-energy conversion, specialized plant-based phytoremediation, …

Geodyn Solutions stands at the vanguard of transforming the environmental remediation landscape, pioneering advanced technologies to turn neglected landfills into sources of …

ZERO MUNICIPAL WASTE

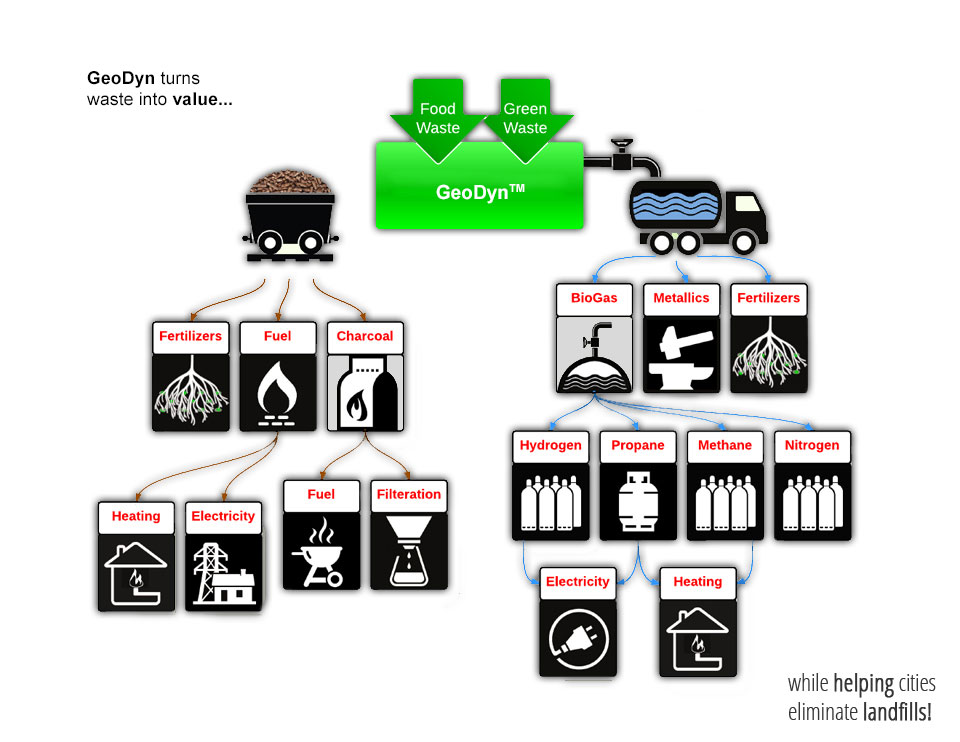

GEODYNTM Solutions started with a simple goal. Eliminate the need for landfills by developing a system that efficiently produces marketable products from all types of solid waste. The result is our Total Waste System and our Organic Waste Processor. Both systems start with shredders featuring a proprietary design, created from the ground up. shredder on the market can produce uniformly sized material quicker or more consistently than GEODYNTM Solutions system. Tested on the toughest materials (palm fronds and plastic sheeting), our shredders can process up to 15 tons-per-hour to uniform sizes of 50 millimeters or less.

This is vital to the process as a small uniform size allows our system to quickly kill bacteria, viruses, and odors. We then use a proprietary press to remove liquids for treatment to irrigation water standards. The remaining solids then travel to the processing unit. If you have organic waste, our Organic Waste Processors can turn this material into animal feed, fertilizers, or clean-burning energy pellets in under 30 minutes at rates up to 42-tons per hour. If you have trash, the same bacteria/ virus/odor killing process creates energy pellets of 8,000+ BTU in our Total Waste System. Pellets from both systems create electricity at a rate of 1 megawatt per-ton or more.

This is vital to the process as a small uniform size allows our system to quickly kill bacteria, viruses, and odors. We then use a proprietary press to remove liquids for treatment to irrigation water standards. The remaining solids then travel to the processing unit. If you have organic waste, our Organic Waste Processors can turn this material into animal feed, fertilizers, or clean-burning energy pellets in under 30 minutes at rates up to 42-tons per hour. If you have trash, the same bacteria/ virus/odor killing process creates energy pellets of 8,000+ BTU in our Total Waste System. Pellets from both systems create electricity at a rate of 1 megawatt per-ton or more.

Turning Trash Into TreasureTM

EMERGING TECHNOLOGY TRANSFORMING TRASH INTO RENEWABLE ENERGY

All nations must deal with concentrated urban populations and isolated rural communities. GEODYNTM Solutions has the only technology that works well on both ends of the population spectrum. Our systems fit into a surprisingly small footprint (100 ton-per-day systems require less than 300 square meters), which allows deployment of this technology in crowded urban areas. With system-sizes ranging from 1 to 42 tons-per-hour, these systems can also be strategically placed where trash is generated. The ability to effectively size systems would also facilitate placement of closed-loop systems to create electricity from trash generated in rural areas with small populations.

In urban, rural, or suburban utilization GEODYNTM Solutions systems eliminate the costs and environmental issues associated with landfills. In addition, our systems provide customizable solutions for global waste management

– Reclamation of 50 gallons of irrigation water per ton processed.

– The creation of clean/renewable electricity through use of our pellets and SynGas systems (up to 1.2 megawatts per- ton).

– Dedication of organic wastes to produce animal feed and soil amendments/fertilizer to support growing agri- cultural needs.

– Ability to turn all current waste material into useful and sustainable products.

– Elimination of long-distance transportation costs and deter illegal dumping.

Placement in population centers is safe since our pro- cess has zero harmful emissions. We don’t burn waste in our process. We rapidly heat it using a proprietary radiant-heat process. The only emission is water vapor. Similarly, SynGas units create fuel through a zero-emis- sion process. The only emission is in the ultimate creation of electricity, through the use of an internal combustion engine.

GEODYNTM Solutions systems are designed for ease of use so no specialized training is required for efficient operation. We also utilize various remote sensors that allow us to help local operators keep their systems running at peak efficiency. Our systems are designed to run 12 to 20 hours per day, thus capital costs are only a fraction of comparably sized anaerobic digestion or incineration systems. Our process is also more efficient as there is no wasted or unusable material left after processing.

TRUE ZERO WASTE SOLUTONS

IMAGINE ALL THE BENEFITS “GOODBYE” TO LANDFIELD

TIME – Our ability to quickly size and process all waste types into marketable products in less than 30 minutes is unmatched.

SIZE – Our systems fit into the smallest per-ton operating space. They can also be sized to accommodate small local or larger regional needs.

ENVIRONMENTAL PROTECTION – Ours is the only system that eliminates all harmful bacteria and viruses in minutes,

Lower the Carbon CO2 through a zero-emission process. Our unique ability to control moisture enables processed material to burn 300% more efficiently than waste-to-incineration systems, thus producing none of the harmful toxins associated with incineration.

Footprint Globally

QUALITY AND VARIETY OF FINISHED PRODUCTS– Our pellets generate 1 to 1.2 megawatts of electricity per ton. Use of chillers prevents our pellets from degrading. Animal feed and soil products are 100% free of harmful bacteria, thus they require no “maturation” period and are safe to use right from our machines

Green Global Solutions for any waste management need

ZERO WASTE – Not only do we eliminate landfills (one definition of “zero waste”) we also create marketable products with no residue to be discarded or requiring further processing to reach a useful or safe state.

DEPENDABILITY – Our shredders run cool and at low rpm’s (600). Our processor and press at less than 30 rpm, thus no premature wear of internal components. Radiant heat does not touch the processed material and creates no pressurized chambers so our system can be safely opened during operation and easily cleaned after operation. Finally, we have kept moving parts to a minimum and don’t require any computerized controls to operate.

In summary, GEODYNTM systems are uniquely qualified to solve any and all solid waste issues in the world.