Proposal: Geodyn Solutions – Green Water Recycling and Energy Plant in South Africa

Project Overview

- Project Name:Green Loop Utility Plant – South Africa

- Location:To be determined in consultation with local municipalities

- Plant Capacity:Treats 150,000 m³/day of municipal wastewater

- Capital Investment (CAPEX):$250 million (including 20% contingency)

- Electricity Production Cost:$0.19/kWh

- Water Recycling Rate:90%

- Fertilizer Production:From recovered biosolids and nutrients

Objectives

- Transform municipal wastewater into clean water and biosolids.

- Use biosolids to generate electricity using ORC (Organic Rankine Cycle) and heat recovery.

- Recover phosphorus, nitrogen, and potassium to make commercial-grade fertilizer.

- Achieve net water reuse and zero-discharge operations.

- Support sustainable agriculture and grid resilience.

Key Components and Technologies

- Microbial Treatment & Algal Reactors– First stage for organic load breakdown.

- Advanced Membrane Filtration (MBR/UF/RO)– For water purification.

- Sludge Digestion & Dewatering– To concentrate biosolids.

- ORC & Steam Turbine Units– Converts biosolids into heat and electricity.

- Nutrient Recovery Units (Struvite Crystallization)– Extracts NPK.

- Solar Panels & Biogas Capture– Enhances energy efficiency and reduces emissions.

Implementation Steps

Phase 1: Feasibility and Planning (Months 1–6)

- Conduct site selection, EIA (Environmental Impact Assessment), and secure permits.

- Finalize MoUs with local government and utility partners.

- Engage engineering firms and technology partners.

Phase 2: Design and Procurement (Months 7–14)

- Detailed engineering designs.

- Equipment procurement: microbial bioreactors, membranes, turbines, nutrient separators.

- EPC (Engineering, Procurement, Construction) contractor appointment.

Phase 3: Construction and Installation (Months 15–32)

- Civil works: tanks, pipelines, sludge processing.

- Install mechanical, electrical, microbial systems.

- Workforce training and local hiring.

Phase 4: Commissioning and Operation (Months 33–36)

- System calibration, testing, and tuning.

- Start full-scale operation.

Begin water distribution, fertilizer packaging, and electricity sales.

Financial Summary

CAPEX ($250 million including 20% contingency)

- Core Technology & Equipment: $100M

- Construction & Installation: $80M

- Engineering & Legal: $20M

- Contingency (20%): $50M

OPEX (Estimated $15 million/year)

- Labor: $3M

- Energy & Maintenance: $5M

- Chemicals & Microbial Inputs: $2M

- Insurance, Admin, Compliance: $5M

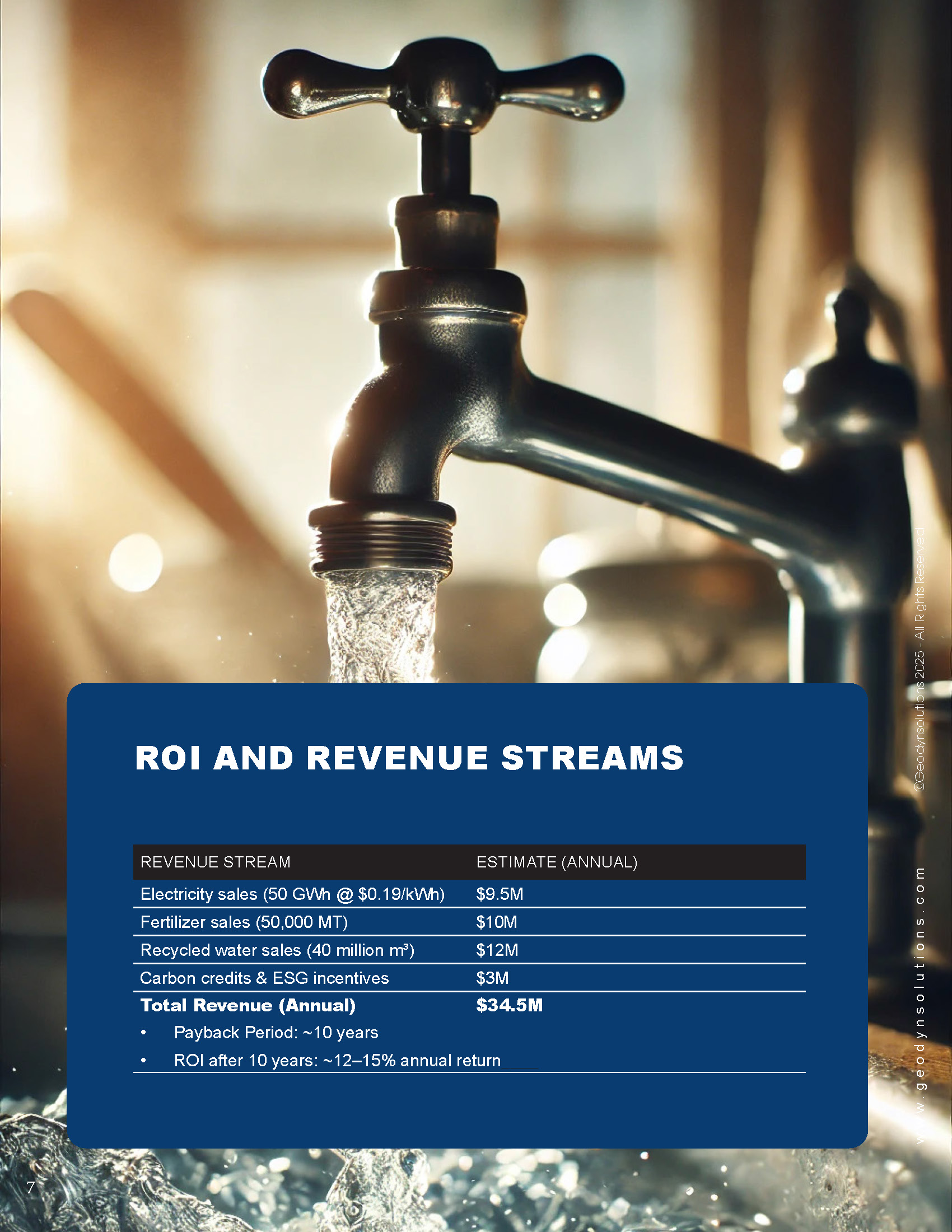

ROI and Revenue Streams

Revenue Stream | Estimate (Annual) |

Electricity sales (50 GWh @ $0.19/kWh) | $9.5M |

Fertilizer sales (50,000 MT) | $10M |

Recycled water sales (40 million m³) | $12M |

Carbon credits & ESG incentives | $3M |

Total Revenue (Annual) | $34.5M |

- Payback Period:~10 years

- ROI after 10 years:~12–15% annual return

Land Requirement

- Total Land Area:20–25 hectares

- Breakdown:

- Treatment facility: 10 ha

- Power & ORC unit: 5 ha

- Storage & packaging: 5 ha

- Buffer & future expansion: 5 ha

Job Creation and Community Impact

- Construction Phase:~400 jobs

- Permanent Operations:120 direct jobs + 300 indirect jobs

- Local contracts for waste transport, packaging, maintenance

- Training programs with local universities for green jobs

Environmental Benefits

- Zero Wastewater Discharge:90% water reuse, 10% safely evaporated or processed

- Carbon Footprint Reduction:Over 50,000 tons CO₂eq avoided annually

- Soil Health Restoration:Organic fertilizer from biosolids and nutrients

- Air Pollution Control:No incineration; low-emission ORC energy recovery

- Methane Capture:From biosolids for energy

- Groundwater Recharge:Safe clean water used for agriculture

Strategic Partnerships

- Technology Providers:ORC turbine firms, membrane tech companies

- NGOs & Development Agencies:For grant support and SDG alignment

- Municipal Authorities:For wastewater supply and infrastructure access

- Buyers:Fertilizer cooperatives, power utilities, ESG investors

Strategic Partnerships

This project embodies Geodyn Solutions’ mission to lead the next-generation water-energy nexus. The $250M investment will:

- Address South Africa’s wastewater challenges,

- Support green agriculture and energy,

- Deliver strong financial returns, and

- Drive environmental and social transformation.