Comprehensive Business Plan: 100 MWh Clean Coal Power Plant with CO₂ Algae Pond and Greenhouse Integration

Executive Summary

This business plan outlines the construction of a 100 MWh clean coal power plant integrated with an algae pond facility and greenhouses. The project is designed to capture and utilize CO₂ emissions to cultivate algae for biofuels, biochar, and food products while using 25% of the captured CO₂ to enrich greenhouses for vegetable production. The electricity generated will be sold at $0.17/kWh or $0.25/kWh, depending on the market. Additional revenue will come from biochar, vegetables, algae-derived food products, and carbon credits.

This innovative project contributes to clean energy, carbon sequestration, and sustainable agriculture, achieving an attractive ROI of 38.5% (at $0.17/kWh) to 59.5% (at $0.25/kWh). It aligns with Zambia’s National Green Growth Strategy (GGS), which promotes development pathways for a low-carbon, resource-efficient, resilient, and socially inclusive economy by 2030. Additionally, the project supports the United Nations Sustainable Development Goals (SDGs):

- SDG 7: Affordable and Clean Energy.

- SDG 12: Responsible Consumption and Production.

- SDG 13: Climate Action.

- SDG 15: Life on Land.

Project Overview

Goals and Objectives

- Generate 100 MWh of clean electricityusing advanced carbon capture technology.

- Capture 90% of CO₂ emissionsand utilize them for algae cultivation and greenhouse production.

- Develop sustainable products: bio-oil, syngas, biochar, and vegetables.

- Diversify revenue through electricity sales, carbon credits, and agricultural outputs.

- Promote environmental sustainability, job creation, and food security.

- Align with Zambia’s National Green Growth Strategy (GGS) and SDGs.

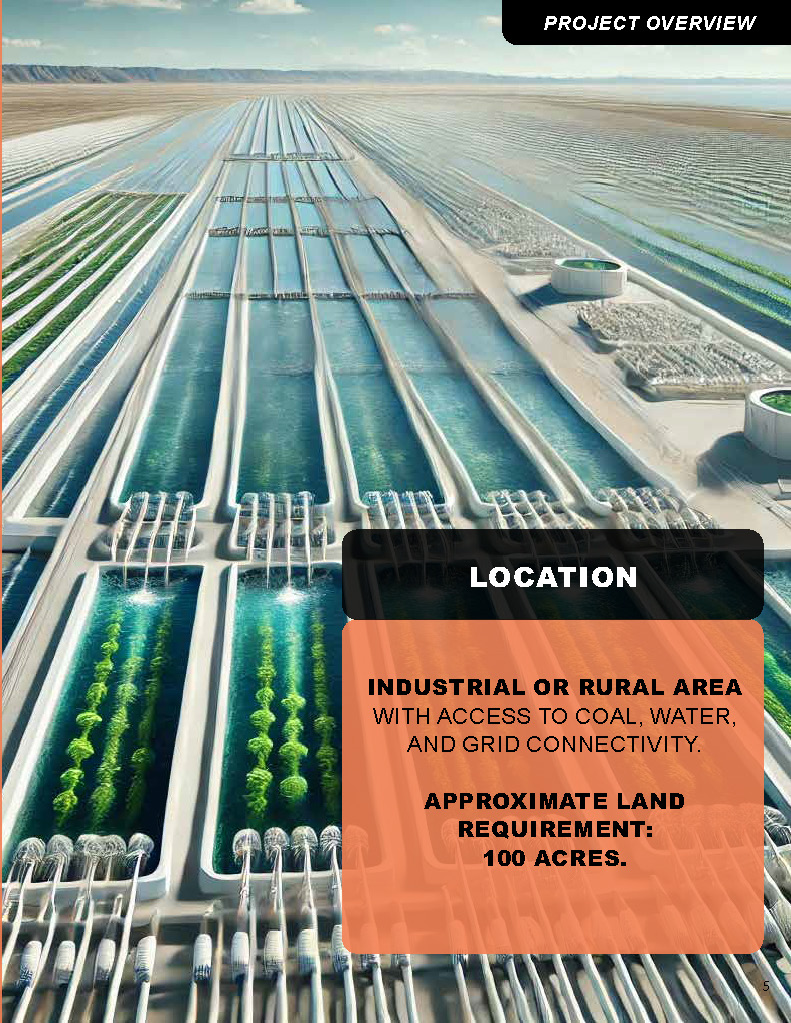

Location

- Industrial or rural areawith access to coal, water, and grid connectivity.

- Approximate land requirement: 100 acres.

Key Features

- Clean Coal Power Plant

- Capacity: 100 MWh.

- Technology: Advanced combustion with 90% carbon capture.

- Purpose: Generate reliable base-load electricity for Zambia’s growing energy needs.

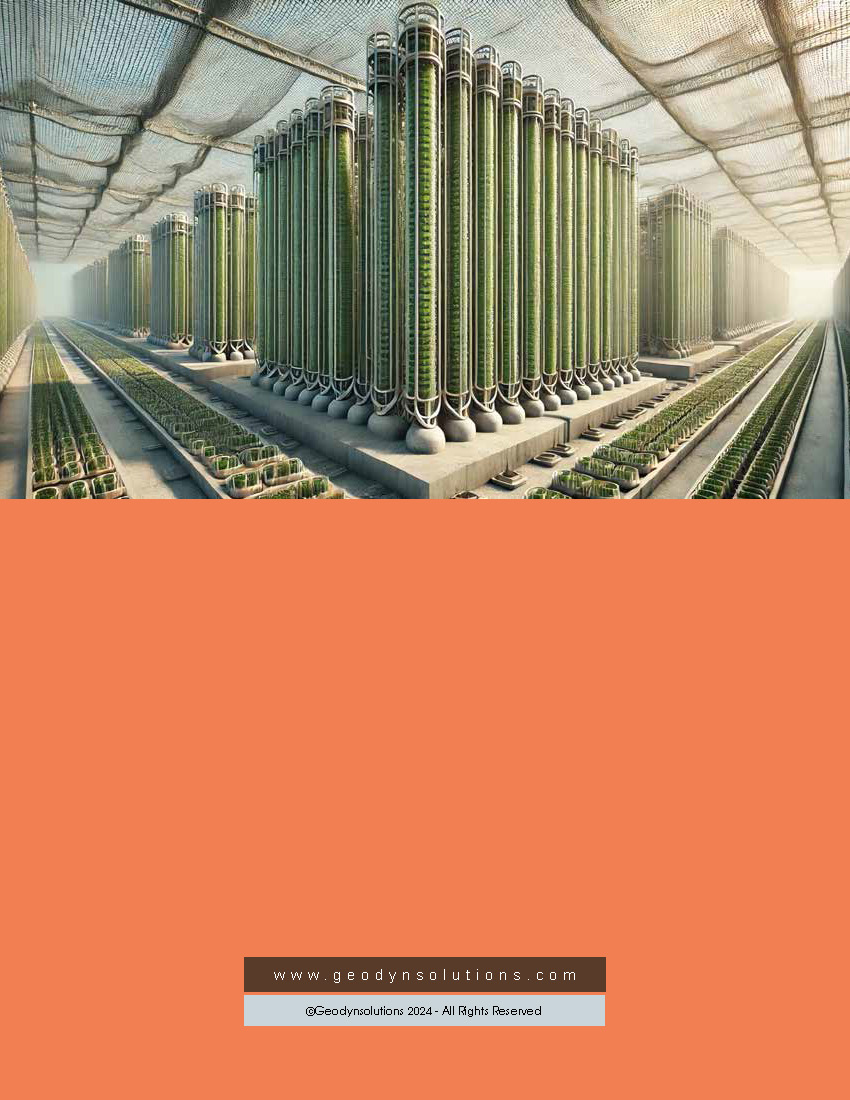

- Algae Cultivation Facility

- Area: 50 acres of raceway ponds.

- CO₂ Utilization: 75% of captured CO₂.

- Output: 200 tons/day of algae biomass.

- 90% Biomass: Pyrolyzed into bio-oil, syngas, and biochar.

- 10% Biomass: Used for food and animal feed production.

- Greenhouses

- Area: 20 acres.

- CO₂ Utilization: 25% of captured CO₂.

- Output: 3,650 tons/year of high-value vegetables (e.g., tomatoes, cucumbers, leafy greens).

- Pyrolysis Plant

- Processes algae biomass into:

- Bio-oil: 50% of biomass (~100 tons/day).

- Syngas: 30% of biomass (~60 tons/day).

- Biochar: 20% of biomass (~40 tons/day).

- Processes algae biomass into:

- Power Generation

- Additional electricity from:

- Bio-oil turbines: Generate 30 MWh/day.

- Syngas turbines: Generate 10 MWh/day.

- ORC systems: Generate 5 MWh/day from waste heat recovery.

- Additional electricity from:

Technical Specifications and Processes

Clean Coal Power Plant

- Technology: Advanced combustion with 90% CO₂ capture.

- Purpose: Provide reliable base-load electricity with minimal emissions.

- Carbon Capture: Captured CO₂ is repurposed for algae cultivation and greenhouse operations.

Algae Pond System

- Area: ~50 acres of raceway ponds.

- CO₂ Utilization: 75% of captured CO₂.

- Output: ~200 tons of algae biomass daily, supporting biofuel production and food security.

Pyrolysis Process

- Input: 180 tons/day of algae biomass.

- Outputs:

- Bio-oil: 50% of biomass (~100 tons/day).

- Syngas: 30% of biomass (~60 tons/day).

- Biochar: 20% of biomass (~40 tons/day).

Greenhouses

- Area: ~20 acres.

- CO₂ Utilization: 25% of captured CO₂.

- Outputs: ~3,650 tons/year of vegetables for local markets.

Power Generation Units

- Primary Source: 100 MWh from the clean coal plant.

- Supplementary Sources:

- Bio-oil turbines: Generate 30 MWh/day.

- Syngas turbines: Generate 10 MWh/day.

- ORC units: Generate 5 MWh/day using waste heat recovery.

Environmental Benefits

- CO₂ Sequestration:

- Prevents the release of 500,000 tons of CO₂ annually.

- Biochar provides long-term carbon storage while improving soil health.

- Sustainable Outputs:

- Algae absorbs 30-50 times more CO₂ than terrestrial plants.

- Contributes to a circular economy by transforming CO₂ into valuable products.

- Food Security:

- Provides 3,650 tons/year of vegetablesand 7,300 tons/year of algae-based food products, addressing local food shortages.

Economic Impact

Job Creation

- Construction Phase: ~2,000 direct jobs and ~4,000 indirect jobs.

- Operational Phase: ~1,000 permanent jobs, including roles in power plant operations, algae farming, and greenhouse management.

Economic Growth

- Boosts local economies through procurement of construction materials and services.

- Generates significant tax revenues and reduces reliance on food imports.

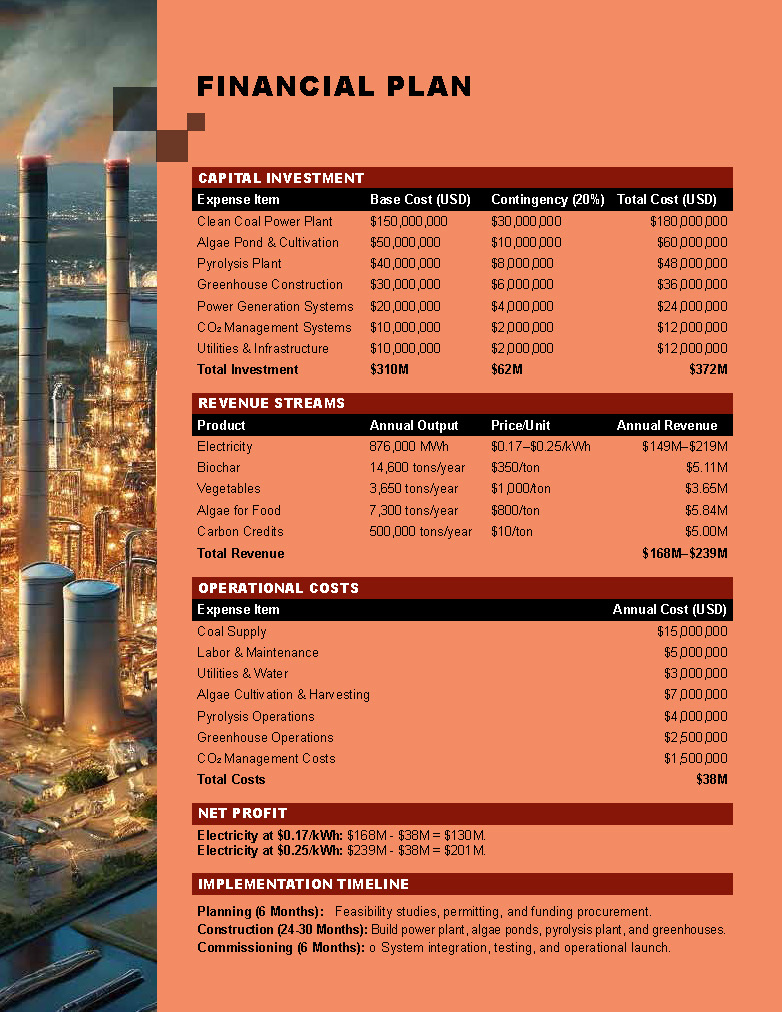

Financial Plan

Capital Investment

Expense Item | Base Cost (USD) | Contingency (20%) | Total Cost (USD) |

Clean Coal Power Plant | $150,000,000 | $30,000,000 | $180,000,000 |

Algae Pond & Cultivation | $50,000,000 | $10,000,000 | $60,000,000 |

Pyrolysis Plant | $40,000,000 | $8,000,000 | $48,000,000 |

Greenhouse Construction | $30,000,000 | $6,000,000 | $36,000,000 |

Power Generation Systems | $20,000,000 | $4,000,000 | $24,000,000 |

CO₂ Management Systems | $10,000,000 | $2,000,000 | $12,000,000 |

Utilities & Infrastructure | $10,000,000 | $2,000,000 | $12,000,000 |

Total Investment | $310M | $62M | $372M |

Revenue Streams

Product | Annual Output | Price/Unit | Annual Revenue (USD) |

Electricity | 876,000 MWh | $0.17–$0.25/kWh | $149M–$219M |

Biochar | 14,600 tons/year | $350/ton | $5.11M |

Vegetables | 3,650 tons/year | $1,000/ton | $3.65M |

Algae for Food | 7,300 tons/year | $800/ton | $5.84M |

Carbon Credits | 500,000 tons/year | $10/ton | $5.00M |

Total Revenue | $168M–$239M |

Operational Costs

Expense Item | Annual Cost (USD) |

Coal Supply | $15,000,000 |

Labor & Maintenance | $5,000,000 |

Utilities & Water | $3,000,000 |

Algae Cultivation & Harvesting | $7,000,000 |

Pyrolysis Operations | $4,000,000 |

Greenhouse Operations | $2,500,000 |

CO₂ Management Costs | $1,500,000 |

Total Costs | $38M |

Net Profit

- Electricity at $0.17/kWh: $168M – $38M = $130M.

- Electricity at $0.25/kWh: $239M – $38M = $201M.

Implementation Timeline

- Planning (6 Months):

- Feasibility studies, permitting, and funding procurement.

- Construction (18 Months):

- Build power plant, algae ponds, pyrolysis plant, and greenhouses.

- Commissioning (6 Months):

- System integration, testing, and operational launch.

Conclusion

This 100 MWh clean coal power plant integrated with CO₂ algae ponds and greenhouses is a transformative project aligned with Zambia’s National Green Growth Strategy and the United Nations SDGs. It offers a scalable solution for clean energy, carbon sequestration, sustainable agriculture, and economic growth, setting a benchmark for Zambia’s transition to a low-carbon and resource-efficient future.