Geodyn Solutions Energy

Geodyn Solutions Energy stands out as a pioneering company with its exclusive lubrication technology that surpasses conventional lubricants by an impressive 50-fold. Their cutting-edge solutions are tailored to minimize heat and friction, even in the most extreme conditions.

Backed by their innovative XPL+® Technology, Geodyn Solutions has introduced a remarkable industrial line of core lubricants and drilling fluids. These products are engineered to safeguard rig equipment while elevating drilling performance. From engines and pumps to top drives and rotary tables, Geodyn Solutions leaves no aspect unprotected, ensuring comprehensive coverage for various applications.

Our Journey

Pioneering lubrication innovation and sustainability

Our Vision

Redefining lubrication for a sustainable future

Our Technology

Advancing lubrication for superior performance.

About Us?

Located in Orange County, California, Geodyn Solutions, Inc. has emerged as a trailblazer in lubrication technology, presenting a groundbreaking solution that significantly diminishes heat and friction. Their exceptional lubricants boast an astounding film strength, surpassing conventional counterparts by more than 50 times.

With a primary focus on the oil & gas and industrial markets, Geodyn Solutions introduces an environmentally-friendly product line that elevates lubrication performance in the most demanding environments. Geodyn Solutions’s XPL+® Technology has undergone rigorous testing and certification by leading laboratories, demonstrating its prowess in real-world applications across top Energy, Transportation, and Mining industries.

Recognized by blue-chip corporations, this advanced lubrication technology proves to be a bottom-line asset. It delivers savings by reducing wear and extending equipment life, enhancing productivity, curbing energy and fuel consumption, preventing costly downtime, and lowering maintenance expenses, all while maintaining an eco-conscious approach.

Geodyn Solutions’s game-changing downhole drilling products have already proven their mettle in over 700 wells, making a significant impact on drilling operations. These products effectively reduce torque, resolve drilling issues, and ultimately result in substantial cost savings.

Behind Geodyn Solutions’s success are seasoned experts with decades of experience in the lubrication industry. Their history of developing and marketing patented state-of-the-art technology is augmented by a dedicated team of industry professionals and technical experts. With partnerships established with some of the world’s largest corporations, Geodyn Solutions is making a lasting impact on a global scale.

Our Products

Products Details

ENGINE LIFE TREATMENT

Introducing Geodyn Solutions Engine Life Treatment, equipped. This advanced treatment forms a powerful bond with engine metal, delivering exceptional protection against heat and friction. Notably, it reduces wear, especially during start-up when motor oil is yet to circulate. Whether it’s a lawnmower or a container ship, Engine Life Treatment enhances the engine’s lifespan and performance, ensuring peak efficiency throughout its operation.

Our product contains a powerful combination of features:

• XPL+ Xtreme Pressure Lubrication

• Metal bonding agent

• Anti-wear agent

• Seal conditioner

• Vegetable-based formulation

• Free from solids, chlorine, or harmful solvents!

The bottom line benefits include:

• Increased engine life

• Exceptional performance under high friction and temperature conditions

• Prevention of oxidation and corrosion

• Protection and conditioning of engine seals

• Optimization of engine performance and fuel economy

• Enhanced protection against wear during start-up

• Easier starting in all temperature ranges.

Heavy Duty Oil Stabilizer

Generators, Top Drives, Gear Boxes, Gear Drives, Draw Works, Mud Agitators, Rotary Tables, and B.O.P. Extends Equipment & Maintenance Intervals Death by 50%

Geodyn Solutions Heavy Duty Oil Stabilizer bonds to the metal, reduces friction, and provides unrivaled protection and performance. Increase component reliability to the fullest potential, prolong maintenance windows, and drastically save service costs.

THE OVERALL BENEFITS ARE:

- Exceptional pressure defense stops oil leaking and burning

- Reduces make-up oil and slows blow-by, extending TBN and doubling oil service intervals

- The start is simpler in all temps circumstances seals prevent thermal evaporation

- Engines and gearboxes are quiet.

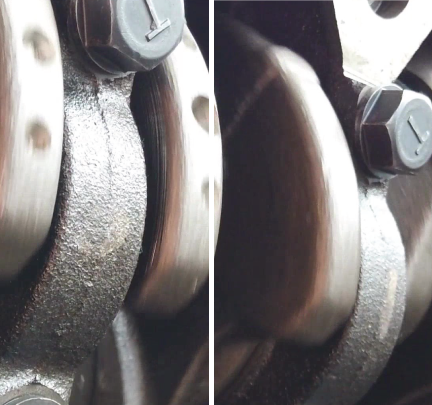

Dodge Cummins: TYPICAL OIL ANALYSIS

The following information was gathered from a significant equipment manufacturer who was informed that quick action was required following an oil analysis test on a Cummins engine because of elevated amounts of iron, chromium, lead, aluminum, and soot. Wear metals significantly minimized after adding Geodyn Solutions Heavy Duty Oil Stabilizer, preserving this engine.

RATIO OF TREATMENT BY VOLUME:

• Increased engine life

• Exceptional performance under high friction and temperature conditions

• Prevention of oxidation and corrosion

• Protection and conditioning of engine seals

• Optimization of engine performance and fuel economy

• Enhanced protection against wear during start-up

• Easier starting in all temperature ranges.

DIESEL MOTOR OIL

A combination of a high performance base oil and XPL+ Technology, which significantly reduces friction and guards against wear, makes up Geodyn Solutions’s 15W40 Heavy Duty Diesel motor oil.

The optimum lubrication protection and performance are provided by this combination.

contemporary, fuel-efficient, low-emission diesel heavy-duty engines.

A strong anti-oxidant ingredient pack in the oil helps to maintain high TBNs, extending oil life and service intervals while also offering exceptional thermal and oxidative stability.

ADVANTAGES

Extreme temperature range +500°F; High TBN additive pack; Viscosity control; Maximum engine protection; Extreme pressure protection; Start-up protection;

BASE OIL CONFORMS TO THE FOLLOWING REQUIREMENTS:

SM, SN, SL, CH-4, CI-4, CI-4 PLUS, CK-4, and CJ-4

Gasket and seal conditioner; Oxidation resistant; Reduces sludge build-up; Deposit control and acid neutralization; Reduces breakdowns; Reduces downtime.

Fuel maximizer

The Fuel Maximizer by Geodyn Solutions is a highly concentrated fuel catalyst/conditioner that boosts chemical energy and solves fuel-related issues. By allowing more oxygen, this improves performance, dramatically lowers fuel use, and dramatically lowers emissions.

lacking Fuel Maximizer

A hydrocarbon is where chemical energy from the fuel is kept. In this condition, hydrocarbons partially burn, producing hazardous pollutants like carbon and soot.

Fuel Maximizer enables

A catalyst called Fuel Maximizer splits apart big particles, speeding the chemical reaction of the fuel and releasing its chemical energy.

Industrial Oil Concentrate

This extreme pressure formulation uses our patented XPL+ technology to reduce friction, heat, and wear in order to significantly boost production efficacy and lengthen the working life of gears, cams, and dies. enhances the efficacy of any oil application

OUTSTANDING PERFORMANCE

Increases feed rates and speed makes surface finishes better decreases power consumption, decreases smoke, and noise, decreases downtime, and decreases wear and tear.

Increases machine longevity decreases electrolysis

APPLICATIONS

- Agearbox

- Cold-heading

- Stamping

- Cutting devices

- Embroidery and dies

- Pumps, and power systems

- Heavy sprockets and chains

- Bearing a ball and roller

Super Duty Gear Oil

Superior 75W-90 Gear Oil with XPL+Technology

Extra protection is provided by this high-performance, super-duty formula for towing, racing, hauling, or using off-road vehicles. Gears, bearings, and seals are protected from wear, shock loading, and high temperatures by superior anti-wear qualities.

Because it is made with XPL+ Technology, which provides 50 times more film strength protection than other gear oils, it can last longer without losing performance.

RATIO OF TREATMENT

Use at 100%. Follow the advice of your manufacturer.

THE OVERALL BENEFITS ARE:

- Dramatically decreases friction, heat, and wear • Thermal stability over a wide temperature range • Provides oxidation stability • Rust & corrosion inhibitor • Compatible with seals and gaskets • Eliminates gear housing clatter

THE BEST FOR EQUIPMENT

- Limited slip differentials; Industrial gearboxes; Manual transmissions; Differentials; Pumps

Limited Slip Gear Oil

Superior 75W-90 / 80W-90 / 85W-140 with XPL+ Technology

In passenger vehicles and truck axles with hypoid gear sets, the API GL-5 Limited Slip Gear Oil is a high-performance, extreme-pressure automotive gear lubricant.

It is made to adhere to the strictest guidelines for extreme gear oil tests. It significantly lowers wear, avoids scoring, lessens oxidative sludge and varnish, and guards against metal fatigue.

RATIO OF TREATMENT

Use at 100%. Follow the advice of your manufacturer.

THE OVERALL BENEFITS ARE:

- Dramatically decreases friction, heat, and wear

- High RPM use

- High film strength

- Designed for demanding applications with high loads

- Thermal stability over a wide temperature range

- Provides oxidation stability Reduces chatter in gear housings, is compatible with seals and gaskets, and has good foam resistance.

BASE OIL CONFORMS TO THESE SPECIFICATIONS

- Ford WSP-M2C197-A, API Service GL-5, MT-1 (SAE 80W-90)

- MIL-PRF-2105E

- O76-A by ArvinMeritor (SAE 85W-141)

- SAE 80W-90 O76-D

- SAE 75W-90 O76-D

- GO-J SAE J2360 Mack

Penetrating Lubricant

No other penetrating lubricant provides the XPL+ lubrication technology that shields metal surfaces from heat, friction, moisture, and the environment and quickly releases rusted or stuck mechanisms. We promise that once you start using this environmentally friendly recipe, you won’t go back to using anything else.

THE OVERALL BENEFITS ARE:

- Lubricates and penetrates

- Prevents rust on metal

- Resists environmental factors, such as saltwater

- Over 600 °F high-temperature resistance Environmentally friendly

REMOVES MOISTURE

Removes moisture and water

Barrier against moisture prevents rusting

SAFE TO USE

- Environmentally friendly Non-toxic

SAFE TO USE

- Removes moisture and water

- Barrier against moisture prevents rusting

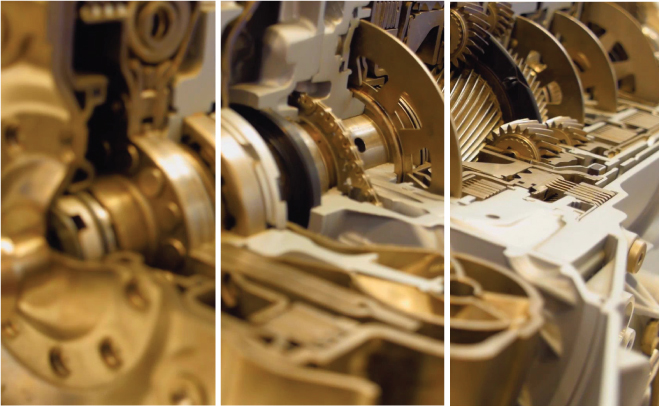

Hydraulic Treatment

Geodyn Solutions Hydraulic Treatment’s cutting-edge XPL+technology offers greater performance, particularly in areas of extreme pressure, to assist keep hydraulic systems operating at their most effective levels, resulting in less downtime and fewer operating costs.

THE OVERALL BENEFITS

- Reduces operational temperatures and friction

- Prevents wear and tear and decreases electrolysis by up to 94%

- Removes moisture

- Prevents rust and oxidation

- Extends the life of the equipment

- Compatible with synthetics and gasoline

- Aids in preserving and caring for seals

- Best run times…reduced downtime

- Cuts down on heavy line pulsating

APPLICATIONS

- Hydraulic apparatus

- Apparatus for transmitting power

- Units with power steering

- The automatic shifters

- Machinery for injection molding

- Railroad machinery

- Equipment for oil fields and refineries

- Pulp and paper mills

- Equipment for smelters and mines

HYDRAULIC OIL

A high-performance anti-wear hydraulic oil, Geodyn Solutions Hydraulic Oil is created to meet and surpass a variety of hydraulic applications and criteria. It is made with premium virgin mineral oils and XPL+ Technology to offer an exceptional anti-wear package.

Together, they offer exceptional resistance to wear, a high level of purity, and great thermal stability for long system life.

USE AT 10% OF TOTAL VOLUME FOR TREATMENT

ADVANTAGES

High thermal and oxidation stability; superior hydrolytic stability; superior demulsibility performance; outstanding rust prevention; exceptional anti-wear technology; reduced fluid friction; designed for high-pressure pumps;

BASE OIL MEETS FOLLOWING SPECIFICATIONS

- Denison HF-0, HF-1, HF-2

- Eaton-Vickers I-286-S and M-2950-S

- Cincinnati Machine P-68, P-69, P-70

- US Steel 127

- DIN 51524, Part 2

- General Motors LH-03, LH-04, LH-06

- Sauer Danfoss

- Rexroth-Bosch

- AFNOR E 48 603

Synthetic Grease

-60°F to 650°F Extreme

Pressure Performance

FOR USE IN:

Rotary Table, B.O.P., High Speed Bearing Applications, Mud Agitators, Mud Pumps, Top Drives

For harsh temperature situations or when low and high speed bearings share the same lubricant, heavy duty complete synthetic multipurpose grease is intended. delivers greater part longevity, decreased downtime, and exceptional protection in even the most extreme corrosive, temperature, or EP situations.

THE OVERALL BENEFITS

- Protection from extreme pressure.

- Capacity to carry large loads.

- Shear stability.

- Resistive to water

- Resistant to oxidants

- Resistant to corrosion

- Clinging power

- Seal Compatibility Aids

- Unstick Free Pipe

- Temperature extremes

APPLICATIONS

- Winches hubs

- Electric motor bearings

- Slides

- Valves

- Linkages

- Sleeves

Rust Pro

Unsurpassed Defense Against Oxidation & Rust

Rust ProTM, a rust inhibitor offered by Geodyn Solutions Lubricants, can offer up to 5 years of protection when stored indoors and 2-3 years of protection when stored outside. for high-salt situations, for carbon steel, or for any exposed metal or painted surface.

proven and utilized by significant oil and gas corporations for their pipe protection and stack-out procedures. Rust Pro is an all-purpose rust preventive that is oil-dispersed, thixotropic, and designed to offer unrivaled long-term protection against rust and oxidation.

Rust Pro has the potential to become fluid with agitation because to its thixotropic properties, which enables the residual film to be self-healing.

Treatable vs. Untreated

3/16-inch-thick bare steel. Rust Pro was applied to the right side and then wiped off. Steel left out in the open for 24 hours while being exposed to 67°F and 63% humidity.

PRINCIPALS PERFORMANCE BENEFITS:

- Ferrous and nonferrous parts are long-term protected for up to 5 years indoors and 2-3 years outside.

- For an even coating of the surfaces, it can be sprayed or brushed.

- Rust Pro turns into a semi-solid once applied to the part’s surface, eliminating drips and runoff.

- Superior clean-ability — an alkaline cleaner will remove it with ease.

RUST PROPEL:

- On areas where salt spray is present.

- When parts will be transported or stored over an extended period of time.

- when corrosion prevention must be at its highest level.