Proposal for Geodyn Solutions: $250 Million Investment in Organic Rare Earth Mining in the Dominican Republic

Executive Summary Geodyn Solutions proposes a $250 million investment to develop a sustainable rare earth element (REE) mining project in the Sierra de Bahoruco, Pedernales Province, Dominican Republic. This project will utilize cutting-edge organic mining technologies, ensuring minimal environmental impact while maximizing economic returns. Additionally, the project includes a $50 million investment in a 30 MW mobile power generation system utilizing Organic Rankine Cycle (ORC) power units to provide reliable, sustainable energy for mining operations. A $30 million contingent fee is allocated to address unforeseen costs, ensuring project resilience and operational flexibility. This investment aligns with global trends in clean energy and critical mineral independence, providing a high return on investment (ROI) and establishing Geodyn Solutions as a leader in responsible rare earth extraction.

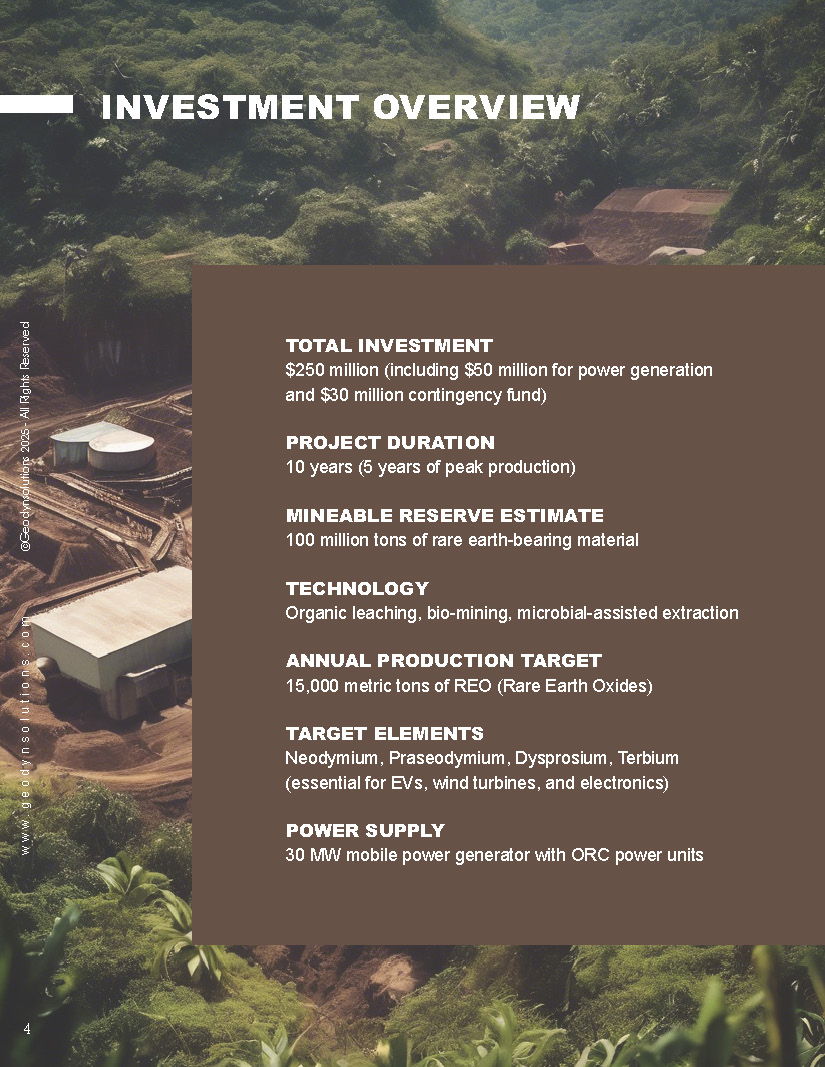

Investment Overview

- Total Investment:$250 million (including $50 million for power generation and $30 million contingency fund)

- Project Duration:10 years (5 years of peak production)

- Mineable Reserve Estimate:100 million tons of rare earth-bearing material

- Technology:Organic leaching, bio-mining, microbial-assisted extraction

- Annual Production Target:15,000 metric tons of REO (Rare Earth Oxides)

- Target Elements:Neodymium, Praseodymium, Dysprosium, Terbium (essential for EVs, wind turbines, and electronics)

- Power Supply:30 MW mobile power generator with ORC power units

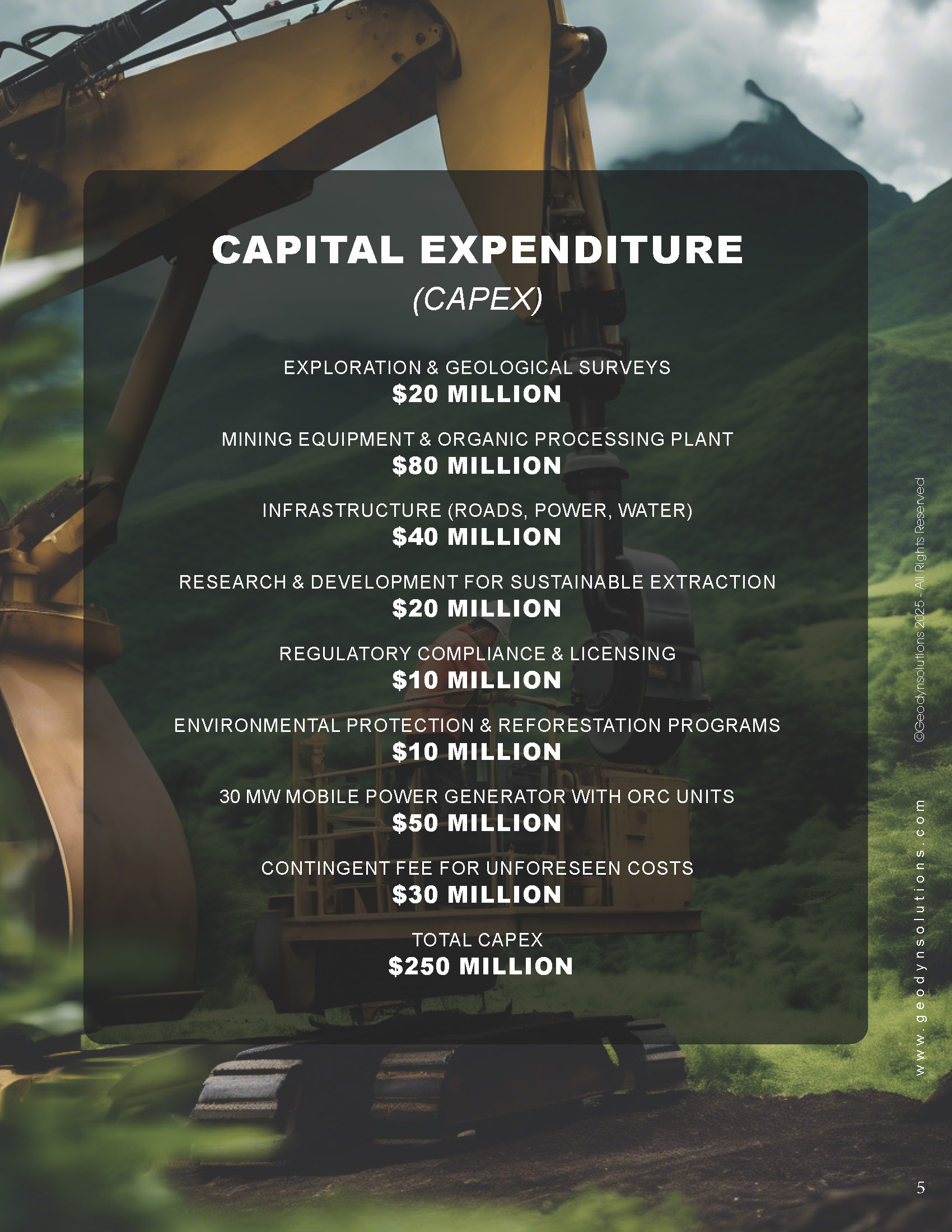

Capital Expenditure (CAPEX)

- Exploration & Geological Surveys:$20 million

- Mining Equipment & Organic Processing Plant:$80 million

- Infrastructure (Roads, Power, Water):$40 million

- Research & Development for Sustainable Extraction:$20 million

- Regulatory Compliance & Licensing:$10 million

- Environmental Protection & Reforestation Programs:$10 million

- 30 MW Mobile Power Generator with ORC Units:$50 million

- Contingent Fee for Unforeseen Costs:$30 million

- Total CAPEX:$250 million

Operational Costs (OPEX) & Revenue Projections

- Annual OPEX: $70 million (inclusive of labor, energy, logistics, maintenance, and environmental protection)

- Average Rare Earth Oxide Price: $10,000 per metric ton

- Annual Revenue: $150 million (15,000 metric tons x $10,000/ton)

- Projected ROI:18-20% per annum

- Payback Period:5-6 years

- 10-Year Net Profit Projection: $900 million

Job Creation & Socioeconomic Impact

- Direct Jobs Created:1,500 (engineers, geologists, plant operators, environmental scientists, logistics personnel)

- Indirect Jobs Created:5,000 (supply chain, local businesses, services, logistics)

- Training & Upskilling Programs:Partnership with local universities for workforce development

- Community Investment:$5 million allocated for education, healthcare, and clean water projects

Power Supply & Sustainability Strategy

- 30 MW Mobile Power Generator with ORC Technology

- Provides efficient, reliable, and mobile power to support mining and processing operations.

- Uses Organic Rankine Cycle (ORC) units, improving energy efficiency and reducing carbon footprint.

- Ensures continuous power supply, reducing dependence on external power sources.

- Renewable & Hybrid Energy Integration

- Solar & Wind Feasibility Studyto further offset energy costs and environmental impact.

- Battery Storage Systemsto enhance energy security and efficiency.

- Energy Efficiency Measures

- Use of high-efficiency electric mining equipment.

- Adoption of smart-grid technologiesto optimize energy use.

- Water recycling and low-energy bio-mining technologies.

Environmental Benefits & Sustainability Measures

- Organic & Eco-Friendly Mining Techniques

- Use of bio-leaching microbes to extract REEs with minimal chemical impact.

- Avoidance of toxic reagents like sulfuric acid and cyanide.

- Reduced water usage through closed-loop water recycling systems.

- Reforestation & Land Restoration

- Active restoration of mined areas with native tree species.

- Carbon sequestration programs to offset emissions.

- Waste Management & Circular Economy

- Recycling of process tailings for secondary mineral recovery.

- Safe disposal and management of residual materials.

Strategic Partnerships & Government Engagement

- Collaboration with the Dominican Republic’s National Mining Firmto streamline permits and operations.

- Engagement with global tech manufacturers for offtake agreements(EVs, wind energy, and semiconductors).

- Partnerships with international organizations for green certificationand investment grants.

Conclusion This investment will establish Geodyn Solutions as a pioneer in sustainable rare earth mining, tapping into one of the most promising untapped REE reserves in the Western Hemisphere. By using organic and eco-friendly extraction methods, the project ensures long-term environmental responsibility while achieving strong financial returns and strategic market positioning.

Next Steps

- Conduct feasibility study and finalize environmental impact assessments.

- Secure necessary permits and government approvals.

- Begin phased development with exploration and infrastructure setup.

- Establish initial pilot production and expand to full-scale operations within three years.

Geodyn Solutions is poised to lead the next generation of responsible rare earth mining.